Maximizing Equipment Long Life: Purchasing Premium Undercarriage Parts Solutions

Maximizing Equipment Long Life: Purchasing Premium Undercarriage Parts Solutions

Blog Article

Key Components: Undercarriage Components for Heavy Machinery

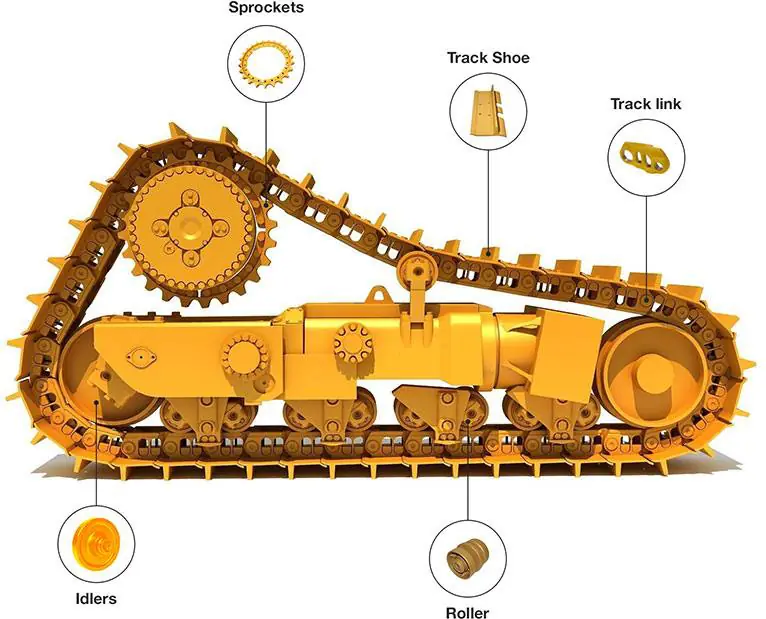

In the world of heavy machinery, the undercarriage acts as a critical structure that makes sure the smooth operation and durability of the devices. Secret components such as track shoes, rollers, idlers, sprockets, and track chains play a crucial role in the capability and efficiency of these substantial makers. Each element adds to the total stability, grip, and longevity of the heavy equipment, making them indispensable for optimum operation. Recognizing the complex interplay of these undercarriage components is necessary for upkeep and operational effectiveness, motivating a better assessment of their significance in the grand scheme of heavy devices capability.

Track Footwear

Track shoes play a critical duty in the efficiency and resilience of hefty equipment's undercarriage system. Track shoes come in different layouts and products to match various operating conditions and terrains.

The layout of track footwear is engineered to supply ideal ground contact, decreasing slippage and improving the device's ability to browse tough terrains. Appropriate upkeep and normal inspection of track shoes are required to stop premature wear and make certain the undercarriage system's durability. Any type of indicators of wear, such as unequal wear patterns or excessive damages, need to be attended to immediately to avoid costly repairs and downtime.

Rollers

Provider rollers aid in sustaining the weight of the devices, while track rollers assist disperse the load and make sure smooth track footwear articulation. Idlers act as a tensioning device for the track chain, keeping correct track tension for optimal performance.

To enhance durability and performance, rollers are generally created from top notch products like built steel, supplying resistance to tear and wear under hefty tons and severe working problems. Proper lubrication is important to minimize rubbing in between the rollers and track footwear, prolonging the life expectancy of both parts. Normal evaluation and upkeep of rollers are important to protect against early wear and possible malfunctions, making sure the constant operation of heavy equipment.

Idlers

Idlers play a crucial function in the undercarriage system of heavy equipment, acting as crucial elements for preserving correct track chain stress and ensuring optimum equipment efficiency. Idlers are accountable for directing the track chain and supporting the weight of the devices. These round rollers are tactically put along the track framework to distribute the device's weight equally, reduce vibration, and enhance security during operation.

Effectively working idlers help avoid premature wear on the track chain and various other undercarriage components, eventually prolonging the life-span of the machinery. They likewise add to fuel performance by lowering moving resistance and minimizing the power called for to move the devices (undercarriage parts). Routine examination and maintenance of idlers are necessary to discover any kind of indicators of wear, misalignment, or damages that could lead to efficiency problems or downtime

Sprockets

Playing an essential duty in his comment is here the undercarriage system of hefty machinery, sprockets are crucial components accountable for moving power from the device to the track chain. Sprockets include toothed wheels or gears that harmonize with the links of the track chain, enabling the equipment to push ahead or backward. By Resources understanding the value of sprockets in the undercarriage system, operators and maintenance employees can successfully take care of these elements to enhance the overall performance and reliability of hefty machinery.

Track Chains

An indispensable part of the undercarriage system in hefty machinery, track chains play a vital function in assisting the activity and supporting of the tools. Track chains are robust metal chains that connect the drive sprocket to the wheels or tracks of the hefty equipment. These chains are made to sustain immense stress, wear, and anxiety while guaranteeing smooth and reliable procedure of the equipment.

Track chains are comprised of private web links that are connected by bushings and pins. The style of track chains is critical as it directly affects the total performance and durability of the hefty equipment. Proper upkeep of track chains is important to protect against premature wear, lower downtime, and extend the life expectancy of the equipment.

Routine inspections, lubrication, and adjustments are required to keep track chains in optimum problem. Failure to keep track chains can lead to increased functional expenses because of frequent substitutes and fixings. Therefore, spending in high-quality track chains and sticking to a rigorous maintenance timetable is key to maximizing you could try these out the performance and durability of hefty equipment.

Conclusion

Finally, the essential components for heavy equipment undercarriage parts include track footwear, rollers, idlers, gears, and track chains. These components are essential for the correct performance and procedure of heavy devices, providing assistance, traction, and stability. It is vital for operators and upkeep employees to consistently evaluate and keep these parts to make sure the security and efficiency of the machinery.

Trick parts such as track shoes, rollers, idlers, gears, and track chains play a crucial role in the functionality and performance of these huge machines (undercarriage parts). Service provider rollers assist in supporting the weight of the tools, while track rollers aid disperse the tons and make sure smooth track shoe expression. Idlers act as a tensioning device for the track chain, maintaining correct track stress for ideal performance

Track chains are robust steel chains that link the drive gear to the wheels or tracks of the heavy equipment.In conclusion, the vital components for hefty machinery undercarriage components include track footwear, rollers, idlers, sprockets, and track chains.

Report this page